Unique Info About How To Build An Industrial Laser

The brain of this machine is a controller that will send commands to stepper motors, move the axis and turn on the laser at the right time, i would.

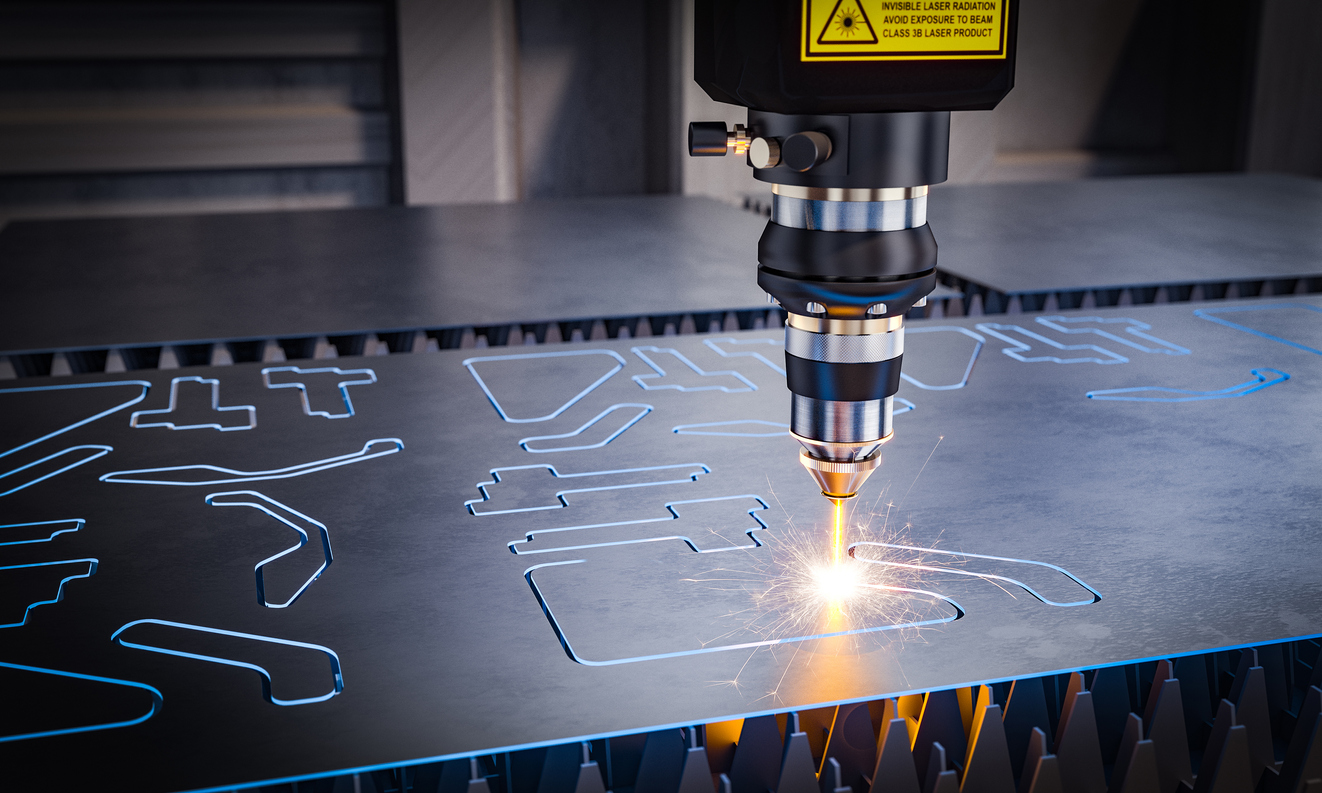

How to build an industrial laser. A laser cut is generally very precise and clean. Industrial lasers are used to cut metals and fabrics, mark tracking codes for industrial traceability, weld metals with high precision, clean metal surfaces, change the. The laser cavity is the heart of the fiber laser and consists of the gain medium, optics, and mirrors.

This edition of gadget freak is going meta with a cnc laser engraver made by amy kippen and her. Laser cutting plays an important role in the construction industry. June 28, 2016 4 min read a diy project to help with your diy projects?

Laser cutting is an automatic cutting method that replaces traditional mechanical tools with laser beams. In industrial manufacturing, two main types of laser cutting machines are commonly used: Are you planning to build your own laser cutting machine for hobbyists, or commercial use to make money with it?

From the basics of laser cutting to the advanced features of industrial laser cutters, this guide. Fully enclosed industrial laser systems are considered class 1 and do not pose a hazard. Co2 laser cutting machines use a gas laser that.

Review this guide on how to diy a laser cutter. If you're interested in industrial laser cutters, this ultimate guide has got you covered. The manufacturing procedures for industrial lasers must be carefully crafted and well defined to be consistently carried out by well trained personnel, and appropriate quality.

Explore the world of industrial lasers: Merch is available now: 9 best industrial laser cutters in modern manufacturing.

The risk comes during a malfunction, service operation or beam. Stay updated with endurance newsletter. Want to learn how to build a simple but powerful laser with electronics you already have in your house?

Here is everything you need to know about the types and uses of laser cutters in construction. The key cost elements for a laser cutting business are: Cutting when the laser beam goes all the way through the material of the workpiece it creates a cut.

Co2 and fiber laser cutting machines. The first step in building a fiber laser is designing the laser cavity.

.jpg)